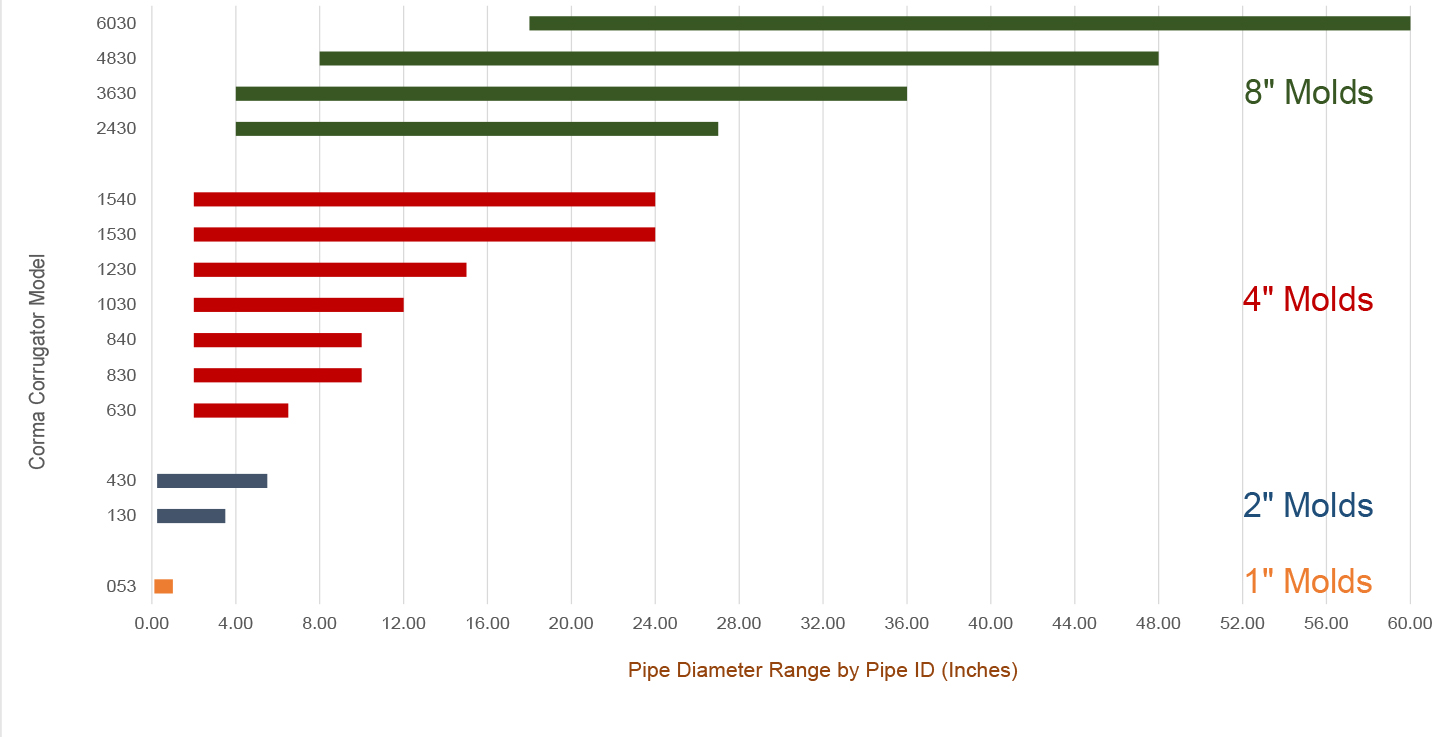

As a leading innovator in the industry, Corma is driven to develop technologies designed to provide clients with key advantages and benefits. Instead of requiring specific mold blocks for each corrugator model, Corma’s Unified Mold Block System maximizes compatibility throughout the entire range of Corma corrugators. The concept was developed to provide pipe manufacturers with a high level of flexibility for expansion opportunities. As an example that the largest 6030 corrugator can use mold blocks from the much smaller 1530 corrugator. Corma can make a positive impact on your bottom line!

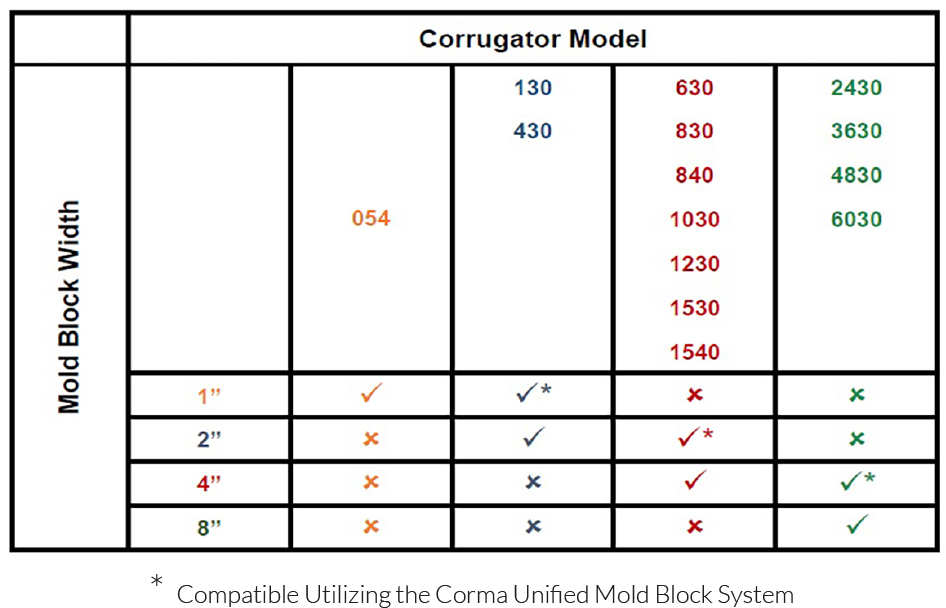

Corma’s lineup of corrugators can be divided into 4 groups, each distinguished by the width of the mold blocks it uses:

Mold blocks within each group are compatible with corrugators in the same group. For example, mold blocks for the 630 can be used on the 1530 since they are both 4” wide.

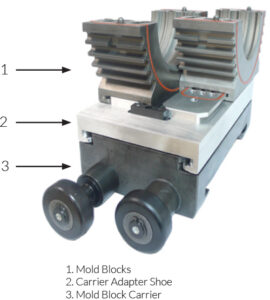

Mold Block Adapter Shoes

In addition, Corma has engineered mold block carrier adaptors that will enable larger corrugators to use the narrower mold blocks from smaller machines. For example, the 6030 can utilize mold blocks from the much smaller 1530 by mounting two 4” wide mold blocks onto 8” wide carrier adapters.

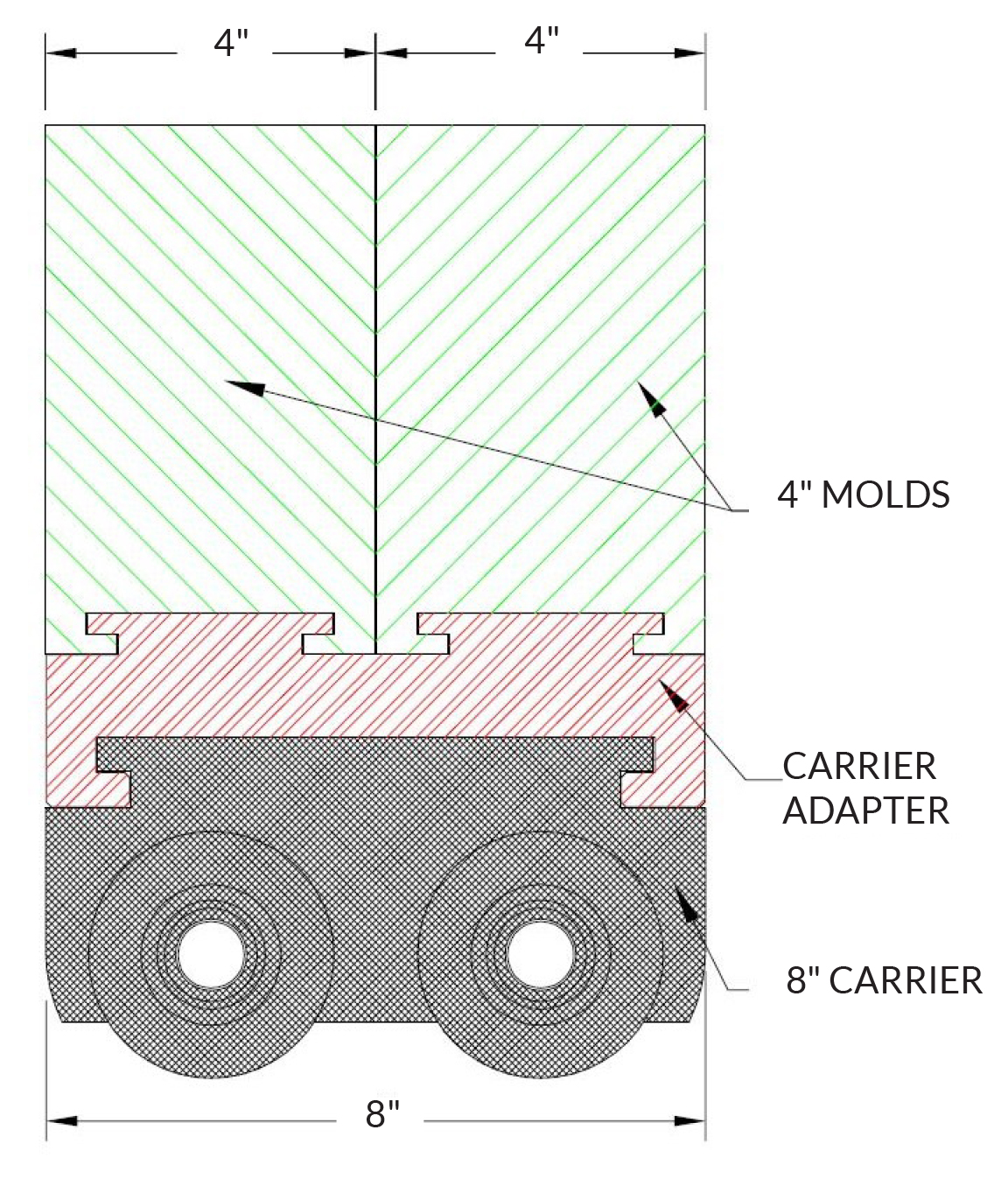

Corma Unified Moldblock System Diagram

The diagram below shows two 4” wide mold blocks mounted on an 8” wide carrier adapter for use in the 2430, 3630, 4830 and 6030 series corrugators.

Compatibility Chart

Corma Mold Block Groups

Technical Data

| Corrugator Model Number* Vacuum Forming or Blow Molding | Pipe Range (mm) | Pipe Range (inches) | Maximum Line Speed** | Maximum Line Speed** | Maximum Output** | Maximum Output** | ||

|---|---|---|---|---|---|---|---|---|

| Min. I.D. | Max. O.D. | Min. I.D. | Max. O.D. | M/min | ft/min | Kg/hr | lbs/hr | |

| 054 | 3 | 40 | 0.12 | 1.6 | 50 | 165 | 40 | 88 |

| 130 | 6 | 110 | 0.25 | 4.5 | 55 | 180 | 360 | 790 |

| 430 | 6 | 160 | 0.25 | 6.3 | 35 | 115 | 450 | 990 |

| 630*** | 50 | 200 | 2.0 | 8.0 | 35 | 115 | 1040 | 2300 |

| 830*** | 50 | 300 | 2.0 | 12.0 | 35 | 115 | 1040 | 2300 |

| 840 | 50 | 300 | 2.0 | 12.0 | 25 | 80 | 840 | 1850 |

| 1030 | 50 | 365 | 2.0 | 14.4 | 30 | 100 | 750 | 1650 |

| 1230 | 50 | 400 | 2.0 | 16.0 | 30 | 100 | 800 | 1760 |

| 1530 | 50 | 700 | 2.0 | 27.5 | 23 | 75 | 1000 | 2200 |

| 1540 | 50 | 700 | 2.0 | 27.5 | 23 | 75 | 1100 | 2400 |

| 2430 | 100 | 800 | 4.0 | 32.0 | 10 | 33 | 1300 | 2860 |

| 3630 | 100 | 1200 | 4.0 | 48.0 | 6 | 20 | 1300 | 2860 |

| 4830 | 200 | 1500 | 8.0 | 60.0 | 5 | 16.5 | 1400 | 3100 |

| 6030 | 450 | 1800 | 18.0 | 72.0 | 3 | 10 | 1500 | 3300 |

| P30/60 | 750 | 1800 | 30 | 72 | 1 | 3.3 | 1300 | 2860 |

| P30/120 | 750 | 3000 | 30 | 120 | 1 | 3.3 | 1500 | 3300 |

| Vertical Corrugator Model Number | Pipe Range (mm) | Pipe Range (inches) | Maximum Line Speed** | Maximum Line Speed** | Maximum Output** | Maximum Output** | ||

|---|---|---|---|---|---|---|---|---|

| V053 | 1 | 20 | 0.04 | 0.8 | 50 | 165 | 30 | 66 |

| V130 | 4 | 110 | 0.16 | 4.5 | 50 | 165 | 215 | 475 |

| Rib-Pipe Model Number | Pipe Range (mm) | Pipe Range (inches) | Maximum Line Speed** | Maximum Line Speed** | Maximum Output** | Maximum Output** | ||

|---|---|---|---|---|---|---|---|---|

| R 2030 | 100 | 700 | 4.0 | 28.0 | 10 | 33 | 1100 | 2420 |

| R 3030 | 100 | 1000 | 4.0 | 40.0 | 10 | 33 | 1300 | 2860 |

* Mold blocks are interchangeable within family (shaded) groupings. Also, mold blocks from smaller corrugators can be used on larger corrugators, using Corma’s Unified Mold Block System and Mold Block Adapter Shoes.

** Line speeds and outputs are theoretical and depend on: pipe diameter; type of plastic; machine model; cooling options; mold track length; temperature and quantity of cooling water; profile configuration; extruder capacity, etc.

*** 630-12 and 830-12 line speed and output based on high speed corrugator configuration