Overview

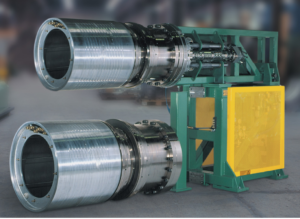

Corma has developed a huge advancement in the technology for the production of large diameter PE and PP pipes. Our motivation was to give our customers a die which was easy to operate and made changeovers quick and safe, The Corma Compact Die boasts low back pressure; allowing for increased outputs. The Compact Die can be adjusted during production.

This technology has been so popular with our customers that they have asked us to incorporate its design for their medium pipe sizes, starting at 12″ (300mm) I.D..

Key Features

Simplified changeovers; – the tooling connects directly to an input die plate that’s fixed on the die stand.

Reduced material wastage; – there is little material wastage during changes and start up.

Ease of start up; – as the tooling is removed as a complete set, the production settings from the previous run is held, reducing rework and improving start-up times.

Heat up times; – the tooling is 50% lighter, there is less material to heat, reducing dwell times and making the tooling more responsive to processing.

Access for change; – as the tooling does not project into the die body, the space required to separate the toolingfrom the die plate is minimal. The compact design of the die tooling makes it easy to handle and install.

Improved centring and wall thickness control; – having 6 point flow control distribution on the die plate allows for material flow and pressures to be balanced, aiding processing on large diameters.