In 1973 Corma introduced our first air-cooled, vertically constructed corrugator. Since then our corrugators have been air-cooled, making it a defining feature of our product line. It has evolved to include our patented Supercooling™ and Insulated Cooling Enclosure Systems, combining to make Corma air-cooled corrugators some of the most energy efficient and productive machines available. By comparison water cooled systems require more maintenance, are prone to water leaks, require more time to change mold blocks and create stress within the pipe.

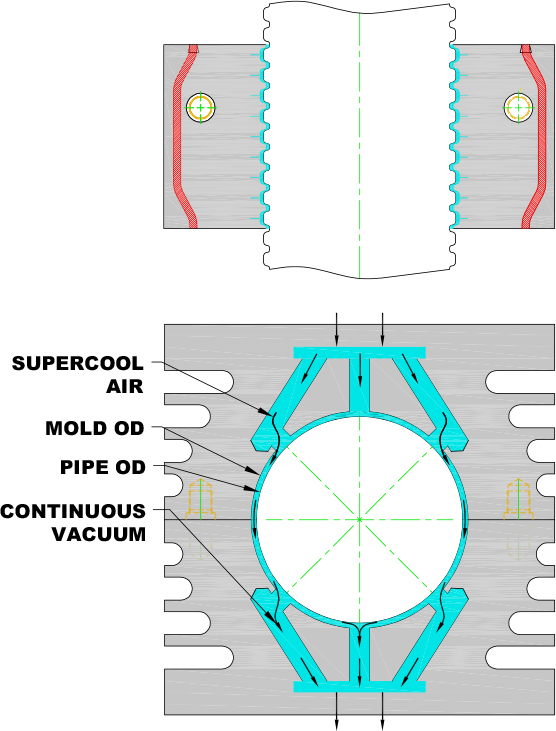

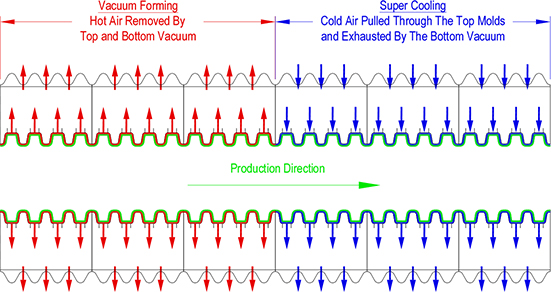

When the plastic sets up and cools down, it shrinks and pulls away from the mold blocks, creating a surface gap between the pipe and the mold blocks which effectively acts as an insulator. The concept of our Supercooling™ Technology is to channel cold air into the gap between the pipe and mold blocks to maximize cooling efficiency. Cold air travels through the vacuum forming slits on one end of our mold blocks into the gap, then exiting out through the slits on the other end. This method efficiently cools both the pipe as well as the mold blocks.

Our Insulated Cooling Enclosure is a climate controlled system that maintains optimal operating temperature throughout the year. This means energy consumption is lower than conventional cooling systems that continuously blow air into the operating environment. Our Cooling Enclosure only requires the energy to cool the corrugator when needed, which prevents overcooling issues as well.

The combination of our Supercooling™ Technology and Insulated Cooling Enclosure increases productivity from 25% up to 50% with less energy usage, low maintenance, quick and easy moldblock changes and consistently produces high quality pipes that have minimal inherent stress. As an innovation leader, Corma is developing new technologies to further enhance the capabilities of your corrugator line. Please stay tuned for more information on how Corma can make a positive impact on your bottom line!

| Corrugator Model Number* Vacuum Forming or Blow Molding | Pipe Range (mm) | Pipe Range (inches) | Maximum Line Speed** | Maximum Line Speed** | Maximum Output** | Maximum Output** | ||

|---|---|---|---|---|---|---|---|---|

| Min. I.D. | Max. O.D. | Min. I.D. | Max. O.D. | M/min | ft/min | Kg/hr | lbs/hr | |

| 054 | 3 | 40 | 0.12 | 1.6 | 50 | 165 | 40 | 88 |

| 130 | 6 | 110 | 0.25 | 4.5 | 55 | 180 | 360 | 790 |

| 430 | 6 | 160 | 0.25 | 6.3 | 35 | 115 | 450 | 990 |

| 630*** | 50 | 200 | 2.0 | 8.0 | 35 | 115 | 1040 | 2300 |

| 830*** | 50 | 300 | 2.0 | 12.0 | 35 | 115 | 1040 | 2300 |

| 840 | 50 | 300 | 2.0 | 12.0 | 25 | 80 | 840 | 1850 |

| 1030 | 50 | 365 | 2.0 | 14.4 | 30 | 100 | 750 | 1650 |

| 1230 | 50 | 400 | 2.0 | 16.0 | 30 | 100 | 800 | 1760 |

| 1530 | 50 | 700 | 2.0 | 27.5 | 23 | 75 | 1000 | 2200 |

| 1540 | 50 | 700 | 2.0 | 27.5 | 23 | 75 | 1100 | 2400 |

| 2430 | 100 | 800 | 4.0 | 32.0 | 10 | 33 | 1300 | 2860 |

| 3630 | 100 | 1200 | 4.0 | 48.0 | 6 | 20 | 1300 | 2860 |

| 4830 | 200 | 1500 | 8.0 | 60.0 | 5 | 16.5 | 1400 | 3100 |

| 6030 | 450 | 1800 | 18.0 | 72.0 | 3 | 10 | 1500 | 3300 |

| P30/60 | 750 | 1800 | 30 | 72 | 1 | 3.3 | 1300 | 2860 |

| P30/120 | 750 | 3000 | 30 | 120 | 1 | 3.3 | 1500 | 3300 |

| Vertical Corrugator Model Number | Pipe Range (mm) | Pipe Range (inches) | Maximum Line Speed** | Maximum Line Speed** | Maximum Output** | Maximum Output** | ||

|---|---|---|---|---|---|---|---|---|

| V053 | 1 | 20 | 0.04 | 0.8 | 50 | 165 | 30 | 66 |

| V130 | 4 | 110 | 0.16 | 4.5 | 50 | 165 | 215 | 475 |

| Rib-Pipe Model Number | Pipe Range (mm) | Pipe Range (inches) | Maximum Line Speed** | Maximum Line Speed** | Maximum Output** | Maximum Output** | ||

|---|---|---|---|---|---|---|---|---|

| R 2030 | 100 | 700 | 4.0 | 28.0 | 10 | 33 | 1100 | 2420 |

| R 3030 | 100 | 1000 | 4.0 | 40.0 | 10 | 33 | 1300 | 2860 |